Boosting Cold Rolling Efficiency with Integrated Infrared and Vibration Analytics

In today’s highly competitive steel industry, cold rolling lines are under constant pressure to increase throughput without compromising quality. Unplanned downtime and undetected equipment failures remain key challenges. To address this, advanced condition monitoring technologies—infrared temperature measurement and vibration analysis—are playing a pivotal role in transforming maintenance from reactive to predictive.

These technologies provide real-time insights into equipment condition, enabling early fault detection, process optimisation, and reduced maintenance costs. When integrated into a unified monitoring framework, they help operators maintain optimal operating conditions, extend equipment lifespan, and ensure consistent product quality even at higher line speeds.

Infrared Temperature Measurement

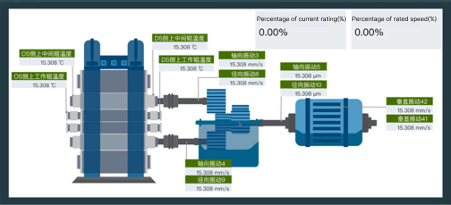

Infrared temperature sensors are widely used in the cold rolling industry for real-time temperature monitoring of key components such as rollers, motors, and bearing systems. This non-contact method allows operators to quickly assess the temperature of critical parts without the risk of mechanical interference or damage. With accurate and continuous temperature data, businesses can detect early signs of overheating, which may lead to equipment failure or process inefficiencies. Implementing infrared temperature measurement facilitates pre-emptive maintenance, reduces the likelihood of unscheduled downtime, and contributes to the overall optimisation of the production process.

Vibration Analysis

Vibration analysis is another key monitoring technique that plays an integral role in predicting the health of rotating machinery. In cold rolling mills, where precision and smooth operation are critical, vibration sensors help detect abnormalities such as imbalance, misalignment, or bearing wear. Through continuous vibration monitoring, companies can perform predictive maintenance, addressing potential issues before they escalate into costly breakdowns. This proactive approach leads to improved operational reliability, reduced repair costs, and enhanced overall equipment effectiveness (OEE).

Integrated Approach for Smart Maintenance

This dual-sensor approach is especially valuable in supporting increased line speeds without compromising product quality. For example, abnormal temperature rises in rollers may indicate excessive friction or misalignment—conditions that are often confirmed by concurrent changes in vibration patterns. By intelligently correlating these sensor signals in real time, the system enables early detection of emerging failures that could otherwise lead to unplanned downtime or quality deviations under high-throughput conditions.

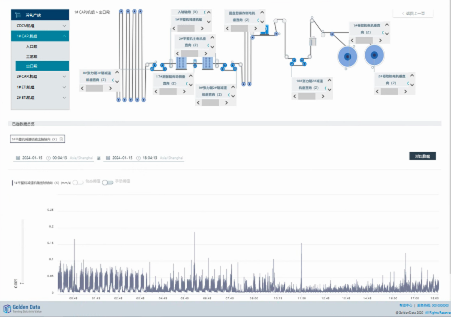

At the core of this intelligent monitoring strategy is Golden Data’s DPlus platform, which goes far beyond basic data collection and visualisation. DPlus integrates AI-powered analytics and embedded industrial logic into lean manufacturing process management, enabling users to move seamlessly from anomaly detection to structured, data-driven responses. Engineers can not only monitor conditions in real time, but also leverage intelligent diagnostics to validate root causes, auto-suggest optimal control adjustments, and deploy targeted process improvements. Through these closed-loop learning workflows, DPlus transforms condition monitoring from a passive oversight tool into an active, intelligent engine for continuous optimisation.

Real-World Case: Increased Line Speed with Guaranteed Quality

A cold rolling CDCM line equipped with infrared temperature and vibration monitoring—powered by Golden Data’s DPlus platform—achieved a without compromising product quality. What made this possible was not only advanced sensing, but also the ability for engineers to track system-wide performance in real time as the line speed increased.

With DPlus, engineers could closely monitor temperature and vibration data from critical components and immediately detect any abnormal patterns emerging during ramp-up. The platform enabled them to identify risk points that limited further acceleration—such as localized overheating or roller imbalance—and respond before they triggered quality issues or unplanned stops.

This real-time feedback loop allowed the production team to push throughput boundaries while maintaining control, using DPlus’s integrated analytics to pinpoint bottlenecks, validate adjustments, and make data-driven decisions continuously. As a result, , and roller lifespan improved by 20%, while the line operated at a significantly higher speed.

Through the integration of infrared temperature sensing and vibration analysis, Golden Data’s DPlus platform provides a powerful foundation for intelligent equipment monitoring and real-time optimisation in cold rolling lines. Beyond detecting anomalies, DPlus embeds AI-driven analytics and structured decision workflows directly into production operations—enabling engineers to identify bottlenecks, adjust parameters, and validate improvements as they increase line speed. In real-world application, this has translated into measurable gains in throughput, quality stability, and asset longevity. As manufacturing moves toward smarter, data-centric operations, we look forward to working with partners who are ready to transform their processes through intelligent, actionable insight.

About the Author

"Hi, I’m Dr Max Cao, I’m passionate about using AI and digital technologies to make industrial operations smarter, faster, and more sustainable. I love turning real-world challenges into practical solutions through innovation and collaboration. If you're interested in AI, digital twins, or industrial transformation, feel free to connect — I’d love to hear from you!"

Choose Golden Data

To better understand, manage, and unlock the value behind data, Golden Data firmly believes that the forthcoming era of data and intelligence will revolutionize the traditional manufacturing industry's production methods and operational models.

Empower through Data

Data becomes an asset of a company whose value appreciates through not only data accumulation but data usage, and the new insights and value created for stakeholders of an organization in optimizing operation.

Work with Experts

Golden Data has a professional team, composed of experienced data experts from renowned universities. The experts team uses a wide range of methods in research and gives advice on data processing and modelling.

Rely on Tenacity

We love the thing we are doing and confident on our solutions. The team tries to eliminate distractions and obstacles in the face of adversity in each project.

Interested in our work?

Turning Data into Value