Revolutionising Plastic Pellet Production with DPLUS: Real-Time Monitoring and AI Integration

Introduction:

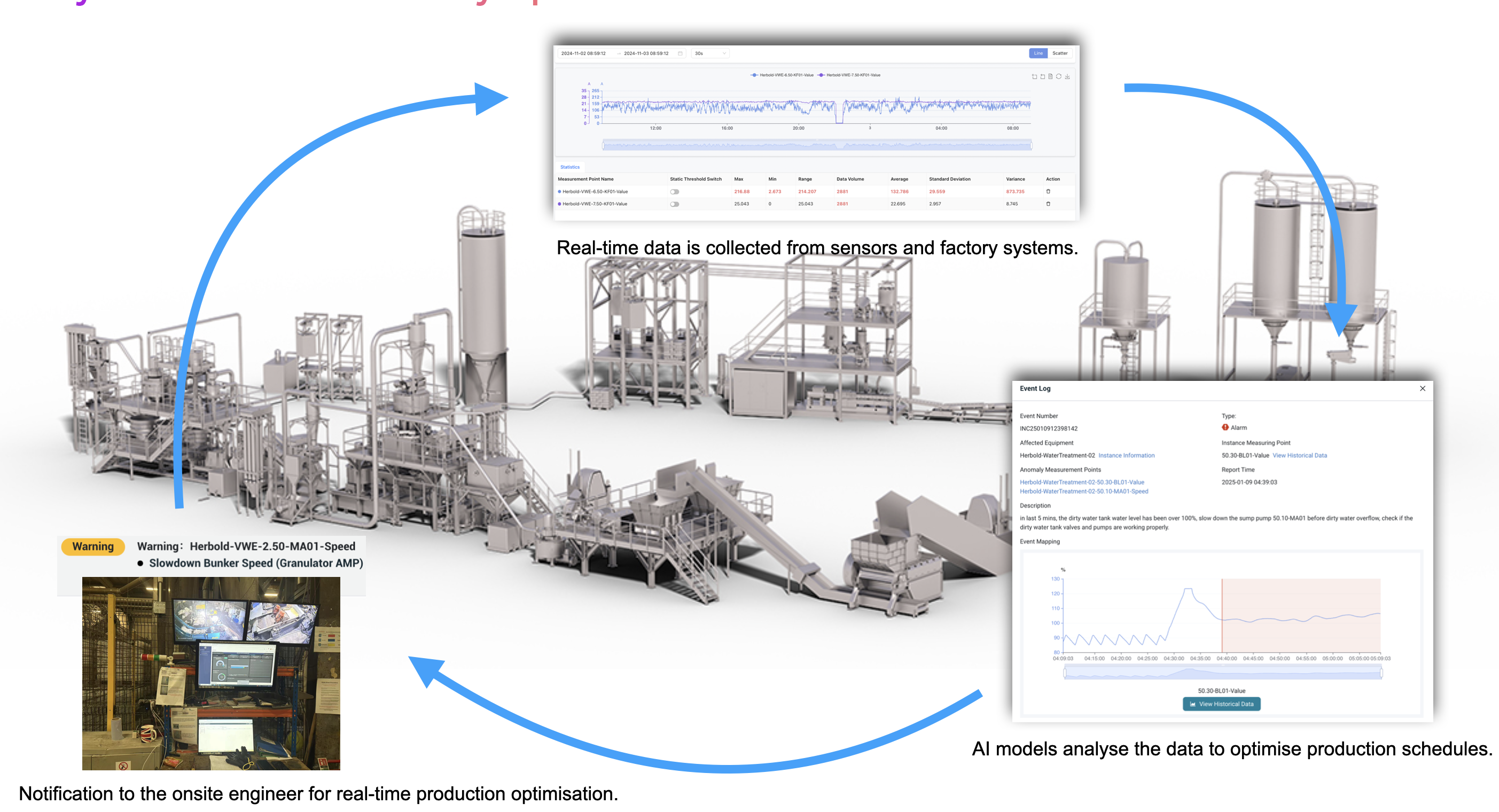

In the fast-paced world of plastic pellet production, efficiency, precision, and sustainability are paramount. This advanced plastic pelleting production line, featuring cutting-edge machinery such as the Herbold washing line, Vecoplan shredder, and EREMA extruder, is further enhanced by the DPLUS platform. With its powerful capabilities in data collection, monitoring, and analytics, DPLUS transforms the production line into a smart, interconnected system.

Inside the Plastic Pelleting Production Line

The production line integrates multiple high-performance machines, each optimised for a specific role in the recycling process:

- Vecoplan Shredder: Reduces waste into uniform particles for efficient handling.

- Herbold Washing Line: Removes contaminants and prepares plastic waste for further processing.

- EREMA Extruder: Converts processed plastic into high-quality pellets with consistent properties.

These components operate seamlessly, but the real magic lies in the DPLUS platform, which enables intelligent monitoring and decision-making across the entire production workflow.

DPLUS: The Heart of Real-Time Monitoring

The DPLUS platform acts as the central nervous system of the production line, ensuring smooth operations and maximum efficiency:

- Comprehensive Data Collection: The DPLUS platform collects real-time data from sensors embedded across the washing line, shredder, and extruder, monitoring key parameters like temperature, pressure, speed, and water levels.

- Advanced Analytics: The DPLUS platform processes data and enables users to view historical data, identify trends, detect anomalies, and gain actionable insights.

- Proactive Actions: Operators receive instant alerts for potential issues, such as motor overloads, water overflow, or speed fluctuations, allowing for immediate corrective action and protecting the production line from the unexpected downtime.

- Event Logging and Visualisation: DPLUS enables user-customised event rules for quick event identification and data analysis. Detailed logs and intuitive dashboards facilitate troubleshooting, support data-driven decisions, and empower process optimisation.

The Benefits of DPLUS in Plastic Pelleting

- Increased Productivity: Real-time insights and alerts ensure all machinery operates at peak performance, reducing downtime and boosting throughput.

- Cost Savings: By predicting and preventing issues before they escalate, the DPLUS platform reduces maintenance costs and extends equipment lifespan.

- Improved Quality: Continuous monitoring ensures consistent output quality, meeting the demands of even the most stringent industrial applications.

- Sustainability: Optimised resource usage and minimised waste and energy consumption contribute to a greener, more sustainable recycling process.

Note: the 3D diagram is sited from Herbold’s website https://www.herbold.com/en/coperion-and-herbold-meckesheim-at-fakuma-2023/

Setting New Standards in Plastic Recycling

With the DPLUS platform at the core of operations, this plastic pelleting production line redefines what’s possible in the recycling industry. By combining advanced machinery with real-time data and AI-driven insights, it delivers unparalleled efficiency, reliability, and sustainability.

Whether you’re looking to modernise your production line, cut costs, or meet environmental goals, DPLUS is the ultimate solution for transforming your operations.

Discover More Find out how the DPLUS platform can empower your business to achieve smarter, more efficient production. Contact us today for a personalised demo!

Choose Golden Data

To better understand, manage, and unlock the value behind data, Golden Data firmly believes that the forthcoming era of data and intelligence will revolutionize the traditional manufacturing industry's production methods and operational models.

Empower through Data

Data becomes an asset of a company whose value appreciates through not only data accumulation but data usage, and the new insights and value created for stakeholders of an organization in optimizing operation.

Work with Experts

Golden Data has a professional team, composed of experienced data experts from renowned universities. The experts team uses a wide range of methods in research and gives advice on data processing and modelling.

Rely on Tenacity

We love the thing we are doing and confident on our solutions. The team tries to eliminate distractions and obstacles in the face of adversity in each project.

Interested in our work?

Turning Data into Value